There are over 393 different wiper options offered from the top 3 manufacturers of cleanroom wipes. Each wipe has different features and benefits. Selecting the right lint-free wipe can be overwhelming, so how do you start the selection process?

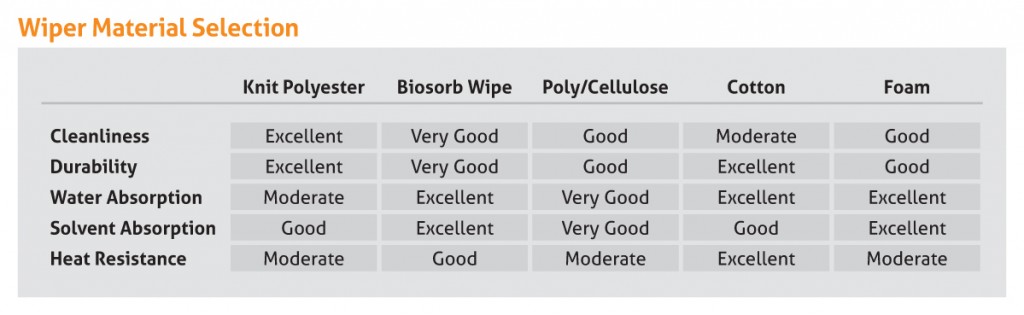

Let’s start by understanding the materials used to make cleanroom wipes. The chart below introduces the general characteristics of the common materials used.

Knit Polyester Wipes

(Suggested ISO Class 3-4)

Knit polyester wipers are made with 100% continuous filament knit polyester. Typically offered in single knit, light weight material or double knit heavy weight material. The double knit polyester is more durable and less likely to snag. Polyester absorbs solvents well, however it absorbs water poorly. Polyester can also be cleanroom laundered in order to reach higher levels of cleanliness.

Non-woven Wipes - Poly/Cellulose & Polyester

(Suggested ISO Class 6-7)

Non-woven wipers are the most common general purpose material used in cleanrooms. Different substrates are used in making non-woven wipes. Poly Cellulose- A blend of polyester fibers and cellulose fibers. These are very popular as they blend the cleanliness of polyester with the absorbent characteristic of cellulose. Polyester- 100% short fiber polyester non-woven wipes are known for their cleanliness and soft non-abrasive surface.

Cotton Wipes

(Suggested ISO Class 7+)

Knit cotton wipes are very durable and absorbent. They also have a high tolerance for heat. Cotton however does break down creating lint, this makes them not suitable for extremely critical applications.

Foam Wipes

(Suggested ISO Class 5-6)

Foam wipers are made with open-cell polyurethane. Foam wipers are very absorbent of chemicals and water based liquids, however they are not as durable as other cleanroom wiper materials.