Did you know there are over 393 different cleanroom wipe options offered from the top 3 manufacturers of cleanroom wipes? Each wipe has different features and benefits, so which ones are right for your cleanroom?

With the vast selection of cleanroom wipes that are available, it is easy to get overwhelmed with the never-ending choices, however with a simple breakdown starting by determining your needs, we can guide you to the best wipe for your application.

To begin the cleanroom wipe selection process, you first need to determine the wiper requirements for your clean room. This varies from industry to industry but we have wipes to meet everyone’s needs.

Some factors you will need to consider are:

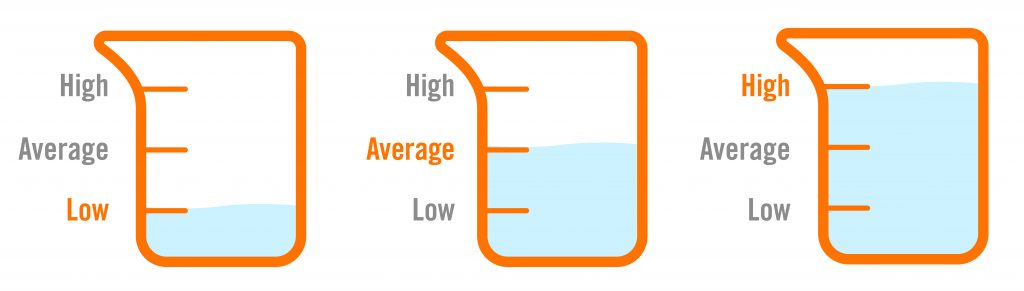

Cleanliness & Particle Release

Will particles being released while wiping hinder the process of what you are creating in your clean room?

Absorption

Does your wiper need to absorb liquids or only used for dry particle pickup? What substances will you be wiping up, are they water based, is it solvent, are you wiping up dry substances? How much needs to be absorbed?

Particle Pick up

What types of contamination are you removing from the wiping surface? Different wipes pick up different materials.

After you have considered the factors above, we can dive deeper into what affects them, to read more, click on the topics below:

Wiper Material

![]()

- Polyester

- Cotton

- Nylon

![]()

- PolyCellulose

- PolyPro

- Rayon

Edge Type

Knife Cut, Laser Cut, Border Heat Seal, what is the difference and which is best for your wiping needs?

Already know what you need?

Think you know what you need but you still aren’t 100%? Angstrom Supply believes our customers should always be able to try our products before making that final commitment, to get your free wiper sample contact us today!